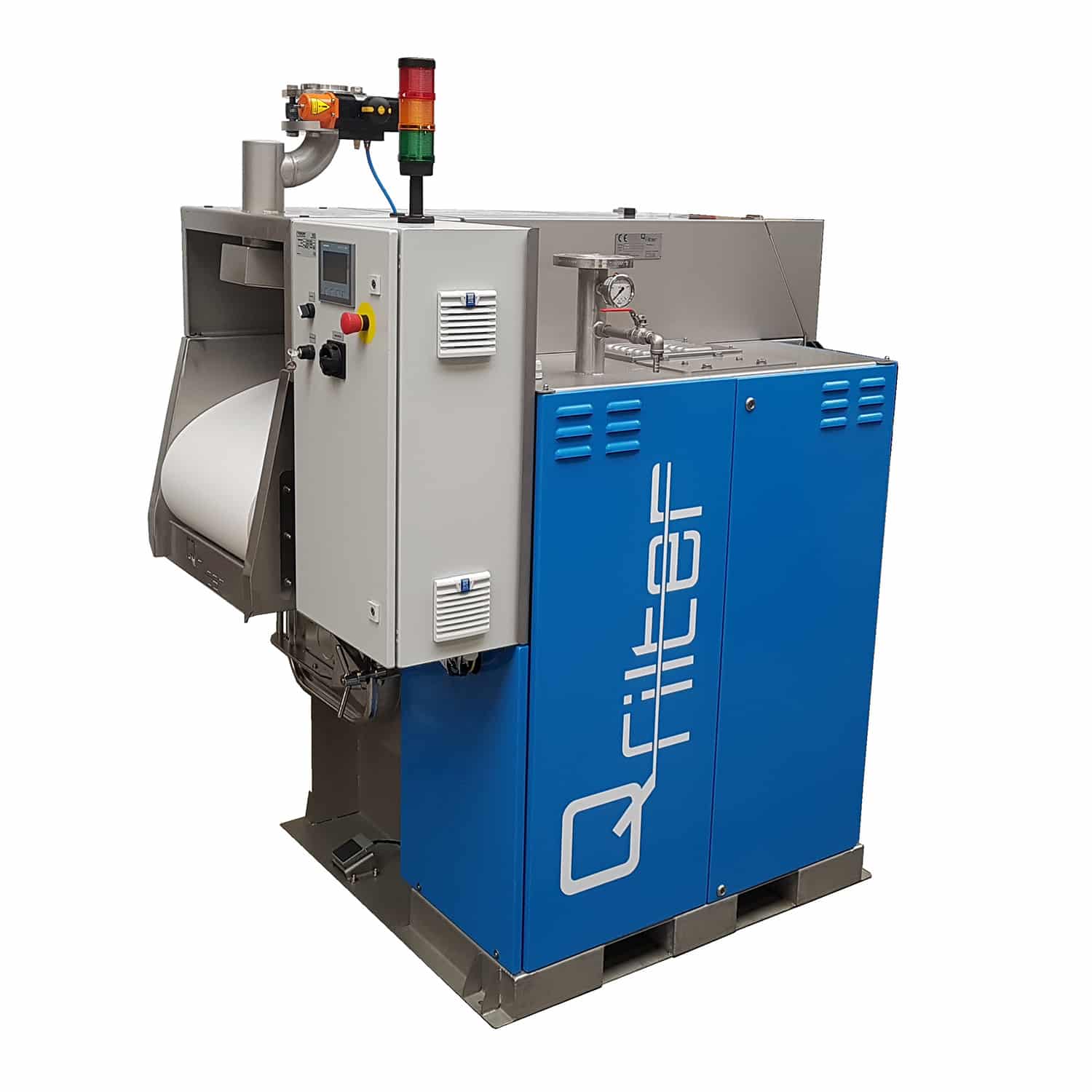

Description

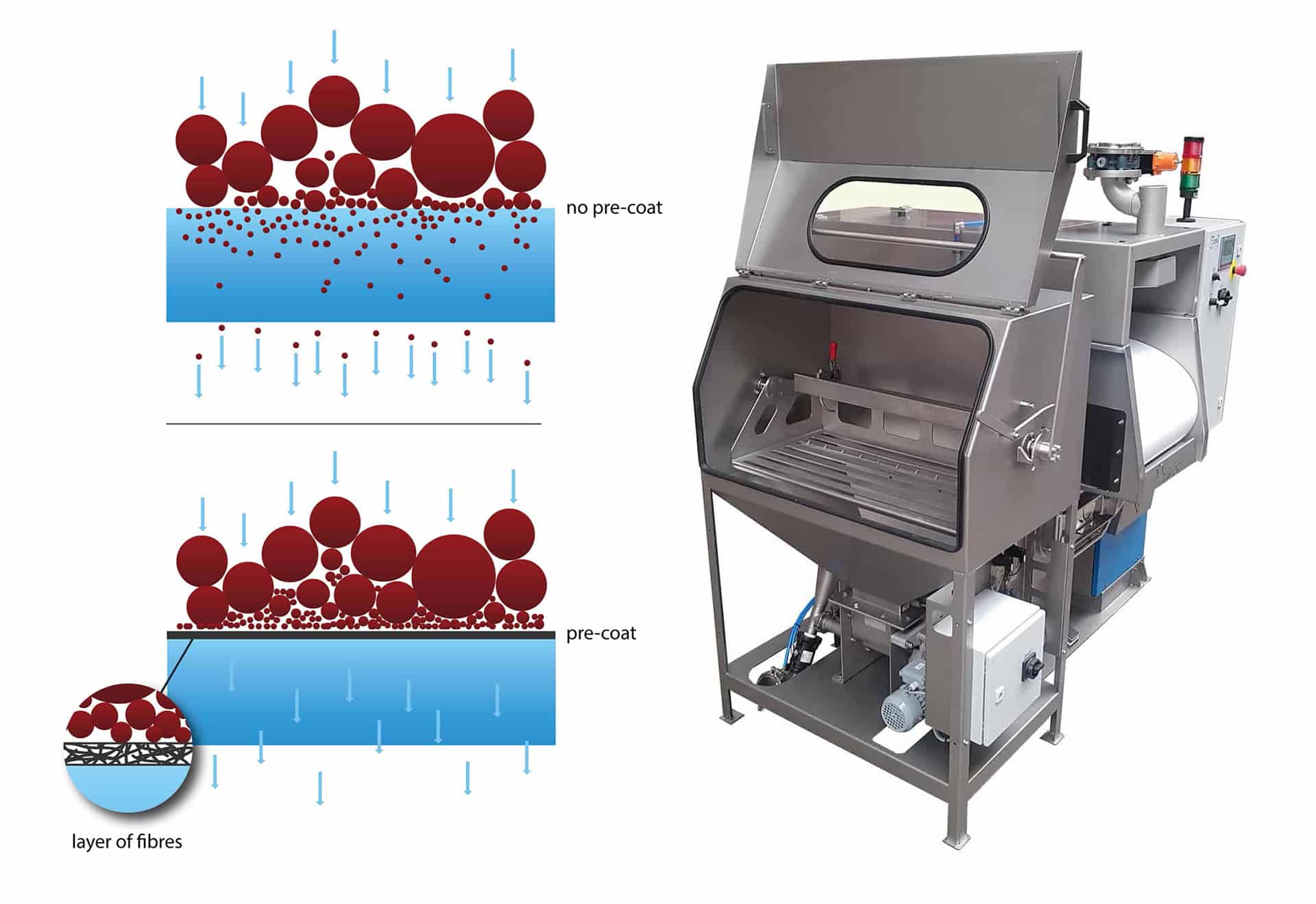

Pre-coat Filtration, for filtration down to 2µm (optional)

Pre-coat Filtration is a high-end filtration method for removal of small particles from contaminated media. Cellulose fibres are actively added to the medium inside the Q-Filter®, building an additional specific filter layer on the filter cloth. This layer improves the filtration significantly because it enhances the formation of the so called ‘filter cake’. As a result, filtration down to 2µm will be achieved. It also prevents clogging of the filter cloth, caused by small particles.

Pre-coat filtration can be added to a Q-Filter® by simply placing a standard module next to the Q-Filter. All connections are available for easy integration.

The Pre-coat Filtration module is very easy to operate. The fibres come in 20kg paper bags and by opening the cabinet, one bag can be easily placed on the grid and clamped into position. Dosing the fibres happens automatically while the control system communicates with the Q-Filter®.

The Q-Filter® 150 series

| Model | QF150 | QF300 |

| material | ss 304 | ss 304 |

| length | 1600 mm | 1600 mm |

| width | 1250 mm | 1750 mm |

| height | 1910 mm | 1910 mm |

| weight | 550 kg | 850 kg |

| capacity | 15 m3/h | 30 m3/h |

| width filter cloth | 500 mm | 1000 mm |

| pump capacity | ** | ** |

| power supply | 1 kW* | 2,5 kW* |

| vacuum capacity | -200 mbar | -200 mbar |

| * without return pump

** depending on application |

||

The Q-Filter® 300 series

| Model | QF150 | QF300 |

| material | ss 304 | ss 304 |

| length | 1600 mm | 1600 mm |

| width | 1250 mm | 1750 mm |

| height | 1910 mm | 1910 mm |

| weight | 550 kg | 850 kg |

| capacity | 15 m3/h | 30 m3/h |

| width filter cloth | 500 mm | 1000 mm |

| pump capacity | ** | ** |

| power supply | 1 kW* | 2,5 kW* |

| vacuum capacity | -200 mbar | -200 mbar |

| * without return pump

** depending on application |

||